Home / All / Plumbing Tools / Pipe Roll Grooving & Cutting Machines / Electric Hydraulic Roll Groover / 2inch to 12inch Steel Pipes for 6-35mm electric Hydraulic Groove Cutting Machine

Categories

- Butt Fusion Machine

- Electrofusion Machines

- Socket Fusion Tools

- Plastic Extrusion Machines

- Plumbing Tools

- PE Pipe Fittings

- Flange Facing Machine

2inch to 12inch Steel Pipes for 6-35mm electric Hydraulic Groove Cutting Machine

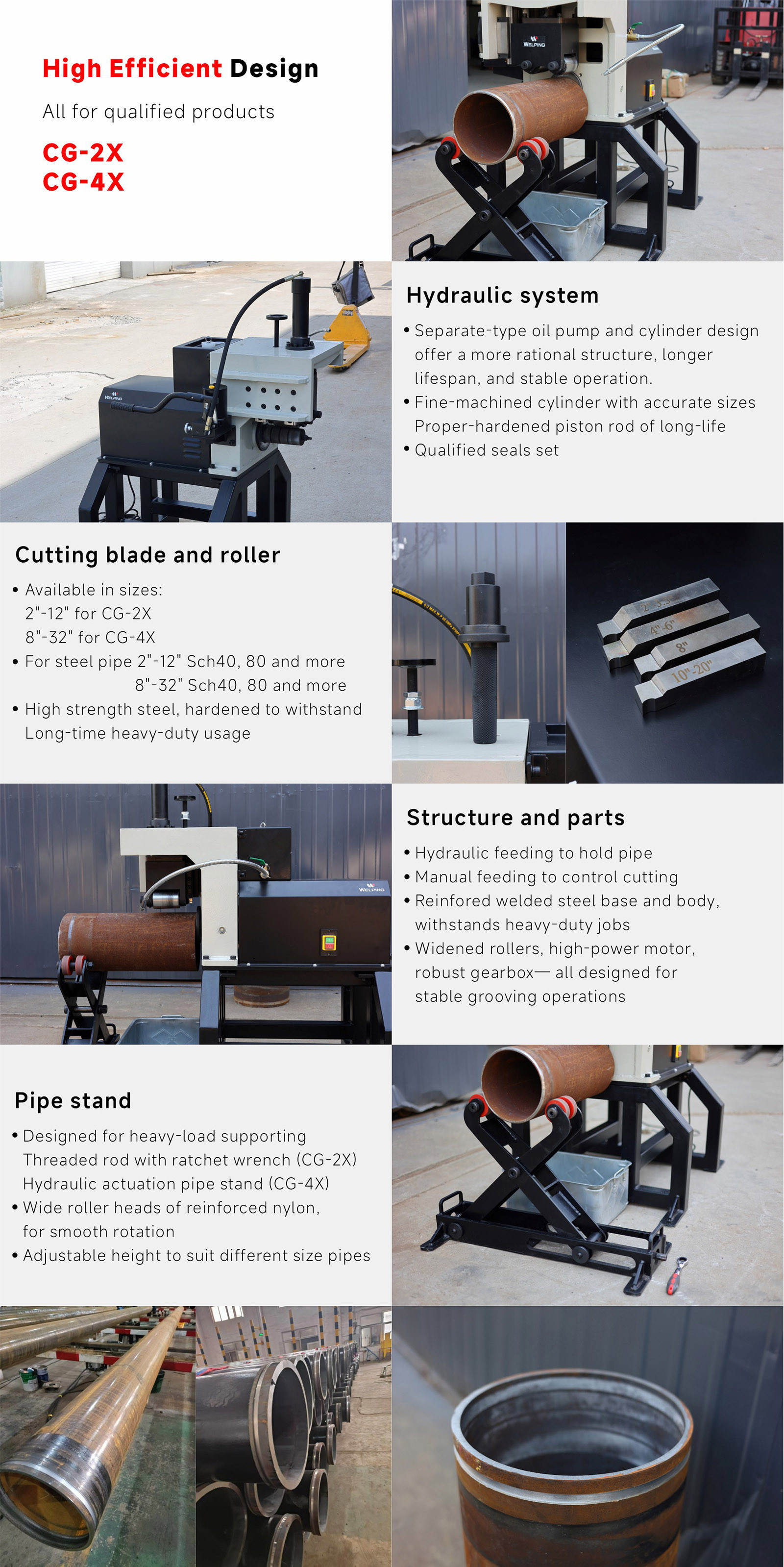

The semi-automatic steel hydraulic electric pipe grooving machine is designed for efficiently creating grooves on steel pipes, primarily used in piping systems such as fire protection, plumbing, and HVAC.

Detail Information

2"-12" Electric hydraulic pipe groove machine

Below are its main functions and features:

Key Functions:

1. Groove Formation: Accurately processes grooves on steel pipes to ensure secure connections with coupling systems.

2. Compatibility: Handles various pipe diameters and wall thicknesses, making it suitable for diverse project requirements.

3. Semi-Automatic Operation: Combines manual control with automated processes to achieve precision and consistency while offering operational flexibility.

Features:

1. Robust Construction: Built with durable materials to withstand high-intensity operations and ensure a long service life.

2. High Efficiency: Semi-automatic operation speeds up the grooving process while maintaining accuracy.

3. User-Friendly Design: Simple controls and an ergonomic structure make the machine easy to operate, even for users with minimal training.

4. Adjustable Settings: Equipped with adjustable rollers and blades to accommodate different pipe specifications.

5. Compact and Portable: The machine's compact design ensures easy transport and storage, ideal for on-site applications.

This machine is a cost-effective solution for professionals seeking reliable and efficient grooving for steel pipe installations.

Standard Parts of CG-2X Roll Groover

|

model

|

CG-2X

|

|

Applicable materials

|

Carbon steel, stainless steel

|

|

capacity

|

2 "~12"(DN50~DN300,Φ60~Φ325)

|

|

power supply

|

220V/380V

|

frequency | 50Hz/60Hz |

Maximum wall thickness | 6-35mm |

Motor Power | 1100W/750W |

Output speed | 23 rpm |

Packaging gross weight | 340kg |

Package Size | 122*91*140cm |

Drive Unit

|

catalog number

|

stage

|

Power |

Voltage

|

Frequency

|

|

998003/998012

|

1PH/ 3PH

|

1100/750W |

220V/380V

|

50/60HZ

|

Standard Parts

|

Item Number

|

Describe

|

net weight

|

|

|

922203

|

Drive roller 2"~3" (Φ60~Φ89)

|

5kg

|

|

|

911204

|

Drive roller 3½ "~6" (Φ101~Φ168)

|

6.7kg

|

|

|

912008

|

Groove roller 8"-12" (Φ219~Φ325)

|

13.2kg

|

|

998149 | Cutting tool 2"~3½” (Φ60~Φ101) | 0.2kg | |

998150 | Cutting tool 4"~6" (Φ114~Φ168) | 0.2kg | |

998154 | Groove roller 8"-12" (Φ219~Φ325) | 0.2kg | |

998151 | Cutting tool 10"~20" (Φ273~Φ508) | 0.2kg | |

998152 | Cutting tool 22"-32" (Φ558~Φ813) | 0.2kg | |

998153 | Foot Switch (only for GC-2X) | 1.5kg | |

Product details

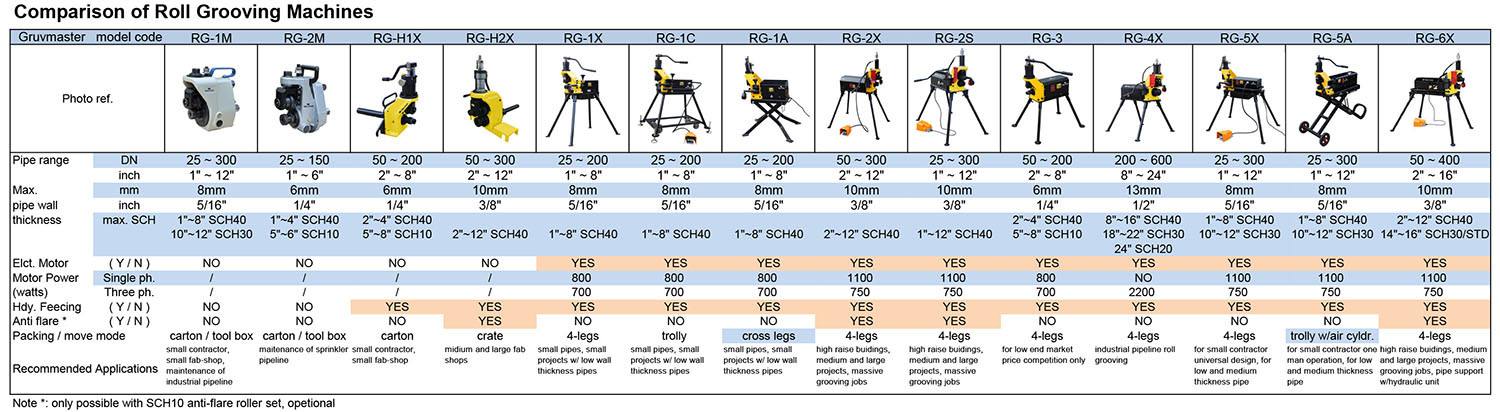

Pipe Roll Grooving Machine Comparasion

download

What can we do for you?

our service

WELPING develops, manufactures and sells equipment and systems for welding thermoplastics, consciously focusing on pipe systems as its main application area in this area. Since 2005, we have been in this field for more than 17 years.

Our goal is to help build your reputation by combining industrial-grade design, performance and quality to provide specialized solutions for a variety of mining and industrial, marine, municipal, irrigation, energy and landfill sites.

WELPING strives to be a provider of all things thermoplastic piping, including welding equipment and certified technical training to assist with the installation and fabrication of any plastic piping related project. WELPING continues to expand the supply and use of polyethylene pipe, valve and fitting system designs into new market segments. In addition, we help customers purchase plumbing tools to support their projects. Our success lies in the quality of our products and the knowledge and service of our employees.

Related Products

Review

- Loading...

Please send your message to us

Welping is dedicated to the manufacture ,sale and repair of machinery for welding and piping equipment.Plastic Welding and Piping Solutions, all solutions for your needs in a single supplier.Let us know how we can help

- *Name

- *Title

- *Content