Home / All / Butt Fusion Machine / Hydraulic Butt Fusion Machines / Hydraulic HDPE Pipe Fusion Welding Machine 1800mm

Categories

- Butt Fusion Machine

- Electrofusion Machines

- Socket Fusion Tools

- Plastic Extrusion Machines

- Plumbing Tools

- PE Pipe Fittings

- Flange Facing Machine

Hydraulic HDPE Pipe Fusion Welding Machine 1800mm

It is a versatile machine designed for butt fusion of 1200mm to 1800mm pipe and fittings, with durability and reliability.

Detail Information

1800mm Hydraulic Butt Fusion Welding Machine for PE Pipes

DETAILS

HDPE pipe has been used extensively in the piping applications of municipal, industrial, marine, mining, landfill, duct and agricultural industries.

Butt fusion welding is an effective, trouble free connecting method for PE, HDPE pipes. In pressurized piping applications, butt fusion welding machine can provide reliable joints, even as strong as the complete pipe.

The 1800mm butt welding machine is a mechanical butt fusion welder for joining various types of plastic pipe including HDPE,PP,PB and PVDF.

The Butt Fusion Machine is designed to butt fuse pipe sizes 1200mm to 1800mm. It is easy to operate and incorporates a state-of-the-art heating plate, 4 jaws machine body, electric facer, and storage stand.

Fusion with Excellence

※ Special designed

※ Built for heavy-duty welding

STANDARD ACCESSORIES |

|

|

Main Frame

|

1 Set

|

|

Heating Plate

|

1 Set

|

|

Trimmer

|

1 Set

|

|

Reducers

|

1 Set

|

Tool Box | 1 Set |

PARAMETER

|

Mode

|

WP1800A

|

|

Suitable materials

|

PE,PP, PB. PVDF

|

|

Range

|

Standard 1200-1800mm

|

|

Power supply

|

380V/50Hz 3PH

|

Rated power (kw) | 78 |

Heater | 65 |

Facer | 7.5 |

Hydraulic station | 5.5 |

Pressure | 0-16Mpa |

Working Temp. | 170-250℃ |

Temp. deviation | ±10℃ |

Piston area (cm2) | 100.48 |

Hydraulic oil | 46# |

Viscosity | 41.4 - 50.6 cSt |

PRODUCT DETAILS MAP

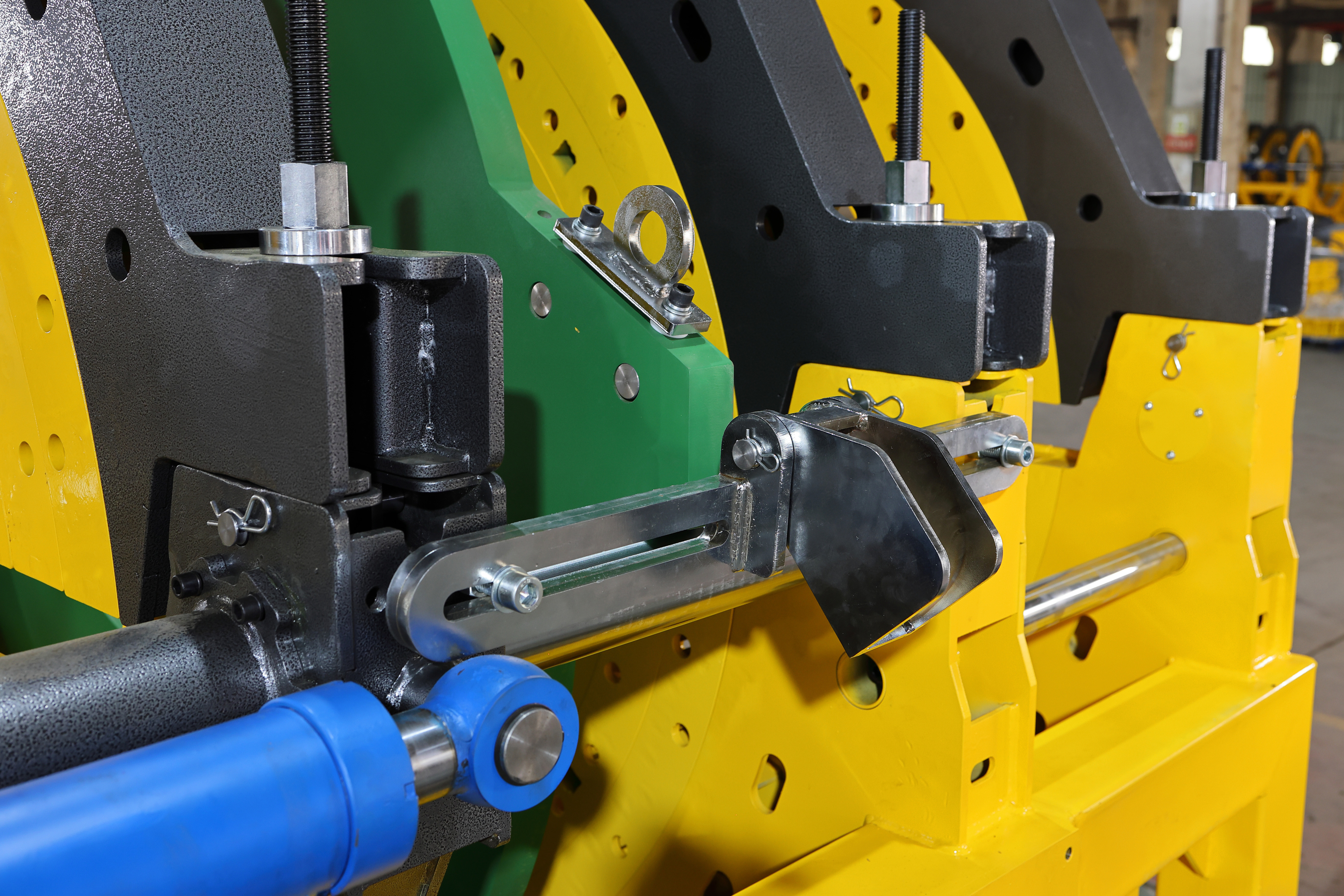

Frame(Carriage)

· Complete steel welded design, with complex reinforced structure, heavy-duty

· Featuring a 3+1 detachable frame structure, the WP1800A offers flexible configuration for pipe fittings as well as easy transportation

· Clamping part with inner anti-slip teeth Independent hydraulic cylinders provide 008 reliable performance and easy maintenance

Hydraulic station

· Integrated hydraulic and electrical control, for easy operation access

· Compact and Enclosure design, shielding splash and dirt

· Equipped with branded electronic parts WELPING to ensure long-term stable operation Welding &Piping

· Standard data logger available to support efficient welding operations

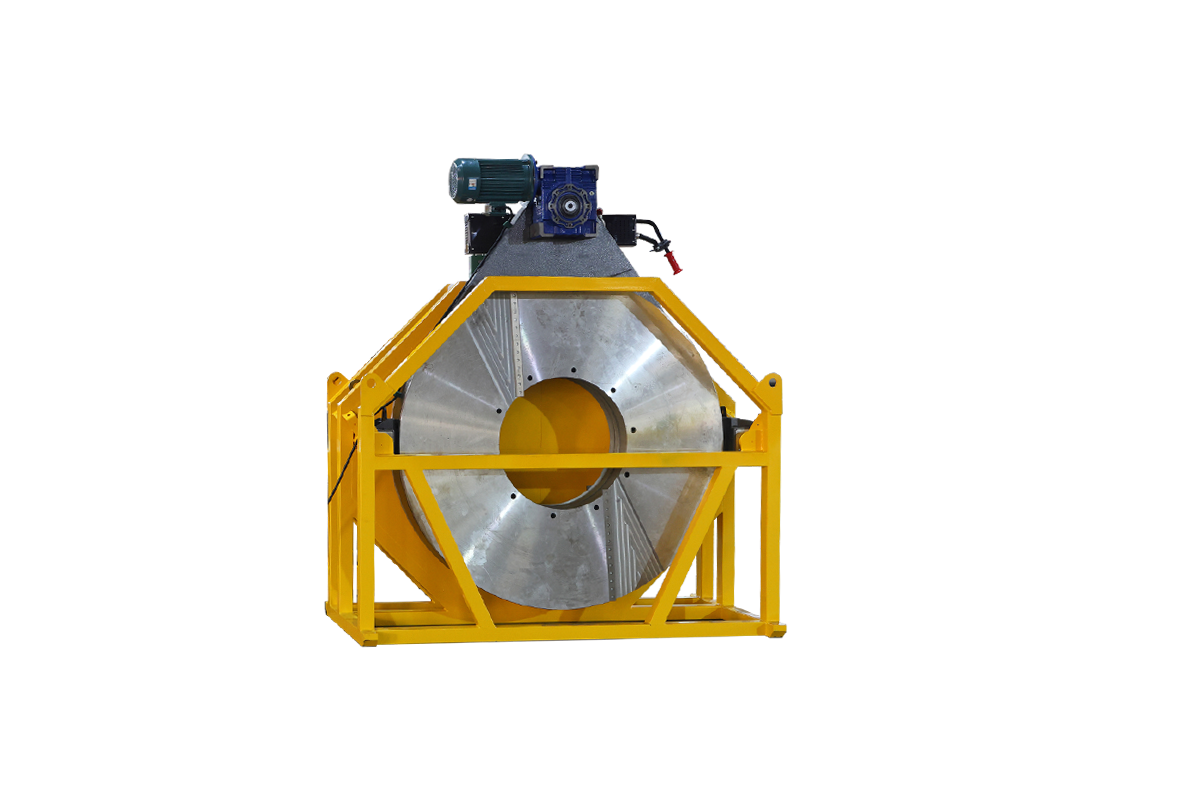

Heating plate

· Thickened cast aluminum body with well-structured internal heating elements, ensuring fast heat-up and excellent temperature deviation control within ±10°℃

· Non-stick PTFE coating supplied by Daikin provides excellent resistance to sticking

· A specialized coating process ensures long-lasting adhesion without peeling

Facer (Milling Cutter)

· Thickened milling cutter plates, solid and reliable

· Dual-blade, HSS material, ensures precise cutting and high efficiency

· Equipped with an internal dual-chain drive system and auto-tensioning mechanism, for heavy-duty applications and long-term

usage without loosening

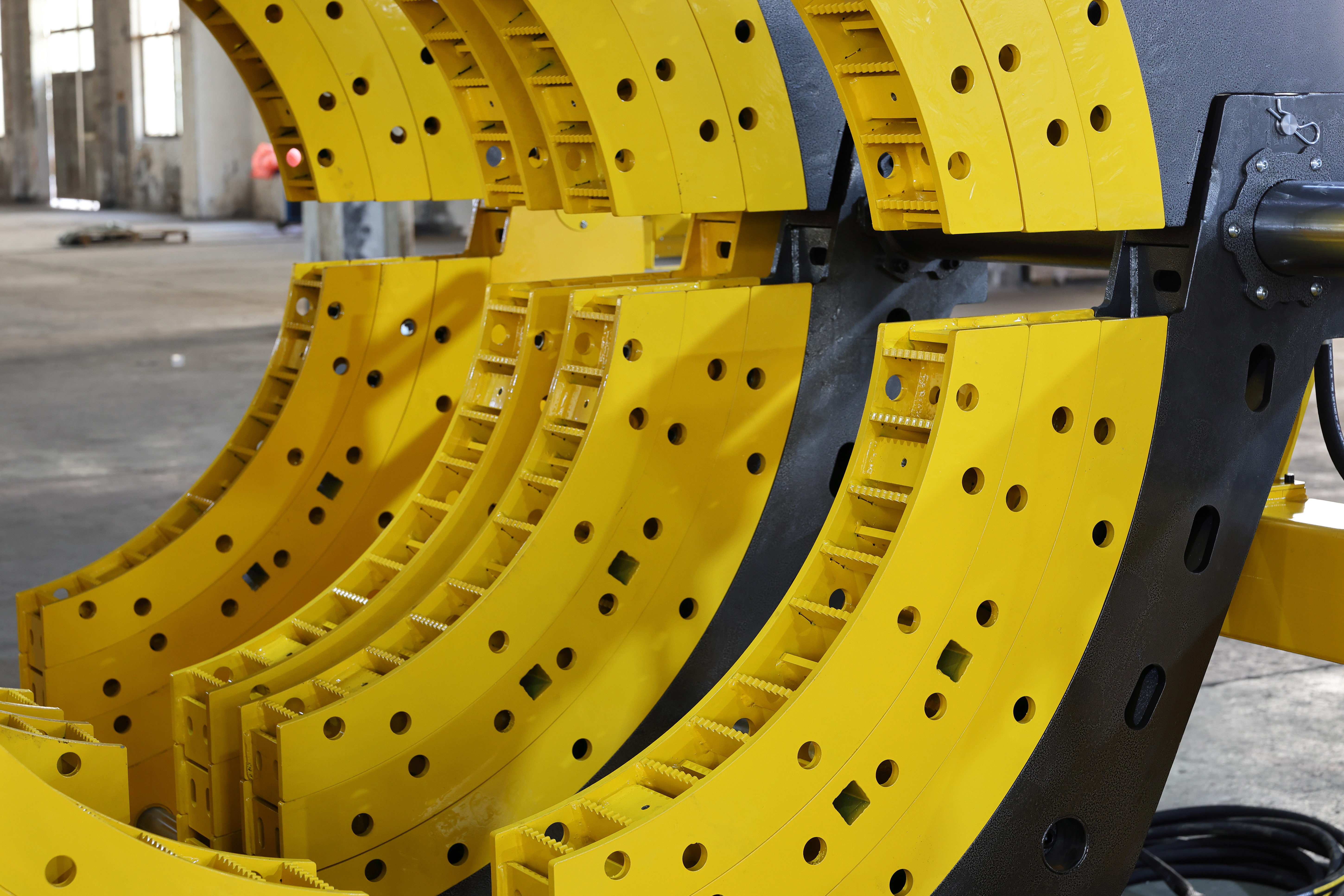

Wide reducers

· Laser-cut, precision-welded clamp inserts for a perfect fit and stable grip

· Multiple anti-slip ridges inside the clamp inserts to enhance pipe gripping force

· 4-piece widened design ensures both easy installation/removal and reliable clamping performance

Hydrauli Crane (optional)

· Custom-built hydraulic lifting arm designed for efficient handling of the facer and heating plate

· Space-saving multi-section telescopic design for compact storage and extended reach

· The base is integrated with the main frame to ensure stability during operation

DOWNLOAD

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 20 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.

Related Products

Review

- Loading...

Please send your message to us

Welping is dedicated to the manufacture ,sale and repair of machinery for welding and piping equipment.Plastic Welding and Piping Solutions, all solutions for your needs in a single supplier.Let us know how we can help

- *Name

- *Title

- *Content